I have been both cursed and blessed with engine failures. Nine of them in 42 years and 7,500 hours are more than my share. The curse is that they happened in the first place. The blessing is that no people were injured nor any airplanes damaged in any of those failures. I present the stories of these events, not because I did anything heroic in surviving them, but rather because there are some lessons for all of us in each one.

What follows is the first segment of my saga of nine engine failures. The second part will come in the next issue of SAFE, the magazine.

Except for an in-flight fire [or maybe structural failure; or midair collision - Ed], the scariest thing for most pilots is an engine failure. I have had them when receiving instruction, giving instruction, and in everyday personal flying. Engine failures can happen any time, day or night, and even right after a satisfactory engine run-up. Even though modern airplane engines don’t fail very often (except on me!), the FAA still requires the engine-failure drill during the checkride for all basic pilot certificates. I have created a Power Point presentation on how I believe engine failures should be handled. You can view it on the EAA webinar website at http://www.eaavideo.org/video.aspx?v=4434579882001.

Lest you think I’m making all of this up, here is a chronological list of my nine engine failures.

1- 8/6/1965 – DeHaviland Beaver, ran a tank dry in the White Mountains, in Vermont, at night

2- 3/26/1977 – Piper Apache, left engine quit on takeoff. Magneto problem.

3- 12/26/2001 – Piper Cherokee 140, student switched tanks, shut the fuel off

4- Early 2000’s, Cessna 172N, ran very rough and shook badly on climb-out, mags (again)

5- 12/16/2006 – three on one flight, a checkride in a Challenger II Long Wing. Engine not properly jetted for cold weather operations.

6- see above

7- see above, again

8- 7/7/2011 – Cessna 177 Cardinal, ran a tank dry on a ferry flight. Fuel selector in wrong position.

9- 3/8/2013 – Champion 7EC, quit on climb-out, carb issue, high-speed fuel circuit blocked.

By far the most common cause of these failures is bad fuel management; direct pilot error. If you have fuel in the plane but you are not directing it to the engine, you have nobody to blame but yourself. I have had three of those types of failure, and two of them were my fault.

My first engine failure was one of the most feared ones. It occurred at night, over inhospitable terrain. I was flying an Army DeHaviland Beaver (as a student pilot, don’t ask) in the White Mountains of New Hampshire. We were humming along at 8,500 feet when that 450-hp Pratt & Whitney radial just stopped dead. No cough, no sputter; it was just like throwing a light switch. Suddenly all you could hear was wind passing over the plane. It was eerie. The instructor said, “boost pumps on, switch tanks.” I reached down and threw up the two boost pump toggle switches and then grabbed to large D-ring fuel selector valve handle (which looked like it belonged on a ship!) and turned it. The engine roared back to life. The instructor said “Now, will you keep track of time?”

Please cut me some slack on this first one. After all, I was still a student pilot. Beavers have a complicated fuel system. The three main fuel tanks are in the fuselage; aft, center and forward. There are also two aux tanks, one in each wing. We had filled them all for the long trip from Bar Harbor, Maine to Mt. Pocono, Pa. With the aux tanks full, the drill was to burn the forward main tank first, and then switch to the aft main. While burning the aft main you transferred the fuel from the aux tanks to the forward main; since the aux tanks would not directly feed the engine. Then you used fuel from back to front. I burned off the forward tank and switched to the aft all right, and did the transfer to refill the forward main. However, I failed to keep running time on the aft tank. I ran it dry, with predictable results. I got three quick lessons out of that experience; Know how your fuel system works; Keep track of time and; Engines quit really fast when starved for fuel. Coughing and sputtering only happens in the movies.

The next fuel-management engine failure occurred when I was checking out Lynn, a fairly new pilot in a Cherokee 140, He had just purchased a partnership, and the checkout was also a three-leg repositioning flight. We did all the flying on one tank. As we approached our home field I suggested that the new owner switch tanks to the full one for the landing. His hand went down by his left leg. I happened to be looking at the engine instruments and saw fuel pressure drop to zero. I started to say, “Lynn, it’s gonna quit”, but I got only as far as a “q” sound at the beginning of the word “quit” when the engine died. I said, “Put that back where it was.” The hand disappeared again, and the engine instantly came alive.

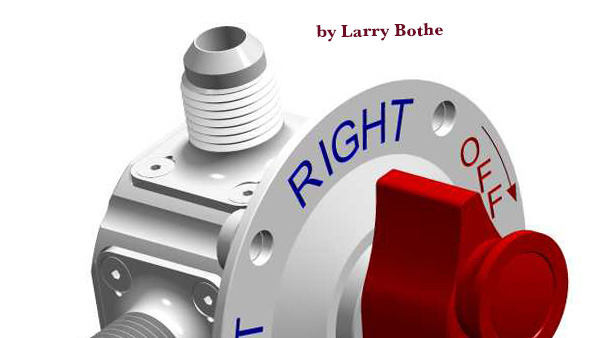

We landed and pulled off the runway. I asked Lynn to show me what he had done. It turned out that he had gone from Left, past Right, into the Off position. I explained to Lynn that there was a detent you could feel at each selector position. He moved the selector back and forth through the positions a few times to experience the detent feel, and then we completed the checkout. The lesson is that you better not ask a student to do something you have not briefed him on, especially if you can’t see what’s going on. And once again, there will not likely be any warning, coughing or sputtering.

Stay tuned for the second half of my saga of engine failures in the next issue.

Larry Bothe is an FAA Designated Pilot Examiner, FAASTeam Representative and Gold Seal Instructor in the Indianapolis, IN FSDO area. He is also a Master Certified Flight Instructor and has over 7,500 hours in more than 80 types of aircraft. Larry is part-owner of a 1961 7EC Champ and may be contacted at LBothe@comcast.net.